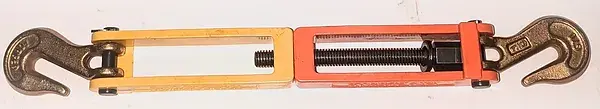

ULTIMATE BINDER

The Orange and Yellow More Affordable

Next Generation Powered Binder

SAFER, LIGHTER, FASTER, EASIER

Ultimate binder is the result of 6 years of developing a safer chain binder that reduces the physical effort and hazards related to operating load binders as well as making load securement easier and faster.

The binder is lighter, powered by a portable impact wrench and can, in most cases, be installed and or tensioned from the ground in less than 10 seconds.

Operators with injuries or reduced physical capabilities find it easier to continue working and driver retention can be improved with this binder.

No winding to open and close , just pull or push ends together.

No handle, binder lock or chain wrap to prevent loosening is required.

Why Ultimate Binder

-

improved safety

-

reduced injures

-

power driven one hand operation

-

reduces physical effort

-

reduced work while on the truck deck

-

faster more efficient operation

-

more compact and easier storage

-

lighter (about half the weight )

-

easier handling

-

hooks positioned for extra reach

-

no handle, gearing or lock

-

can eliminate binder damage to flat surfaces

-

Binder can be drectly coupled with the clevis pins to chain links, slip hooks, cables , nets, etc

Binder Specificaton

-

G70 grade - 3/8 - 5/16 in.

-

Working Load Limit (WLL) - 6600#

-

Minimum Breaking Strength (MBS) - 26,400 lbs.

-

All binders are (tested) to 20,000 LBS - (3 times the WLL) - - 1 1/2 times the WSTDA proof load test requirements.

-

The binder yokes are made from heat treated ultra -high strength medium carbon alloy steel and powder coated for corrosion resistance

-

The Hex. Drive bolt is also made of Ultra- high strength heat treated alloy steel, has a double thickness head and an Acme thread for enhanced strength, ware and corrosion resistance.

-

Yokes are powder coated for corrosion resistance.

-

Grab and slip hooks are commercially available 3/8 in. - G70 hooks and are galvanized for corrosion protection

-

Binder weighs only about 6 lbs

-

overall length - closed - 20 1/2 in. - open - 25 1/4 in.

-

Binders are MOT/DOT and FMCSA compliant

-

follows or exceeds applicable WSTDA and FMCSA recommended criteria.

-

Patents in USA and Canada

Binder Specification Markings

The binder is designed to be operated by a portable impact wrench with one hand when engaged with the head of the central bolt, which, opens and closes the binder.

The impact wrench rotates the bolt through an extension bar connected to a ball universal joint and a 15/16 in. / (24mm) impact socket compatible with the head of the bolt.

The use of an Impact driver significantly reduces the physical force

required by the operator to rotate the handle of a ratchet binder or operate a drill driver, which both require 2 hands.